Not everyone expects ‘wine’ and the ‘Internet of Things’ (IoT) to be used in the same sentence. But one of our employees is challenging this assumption on her own vineyards...

Senior Consultant Fiona Turner is applying digital transformation technologies to her Tasmanian winery in an effort to bring agtech to Australia, and to make better wine in the process. We caught up with Fiona to ask her how...

Jinglers Creek Vineyard harnessing IoT

Fiona is a part owner of a small boutique vineyard in the Tamar Valley, Tasmania.

Jinglers Creek vineyard produces cool climate grapes like riesling, pinot noir, chardonnay, sauvignon blanc, selling them to wineries and vineyards. The winery also makes around 5,000 bottles of wine a year under the Jinglers Creek label. As a small vineyard with two hectares of grapes, 4108 vines, 200 olive trees and a small cellar door, Fiona’s primary focus is on quality not quantity.

Now Fiona is bringing IoT networks and devices to drive efficiencies in her vineyards. And, she’s doing this all in her spare time....

What made you blend digital technologies with viticulture?

My career in digital technologies, my farming background and my interest in agtech made me realize what potential there is for IoT technologies both in my own vineyard, and in agriculture across Australia.

How are IoT technologies helping make your vineyard ‘smarter’?

Because we’re small it’s not always economical to be bringing in additional resources all the time. It’s also challenging to make good decisions based only on what I see and notice. So I started asking ‘How can I get data to help me make some of these decisions?’

Detecting smoke in the air is one example. My consultant would tell me “you need to be careful if there’s lot of smoke because you’ll need to pick the grapes early”. But what does that actually look like?

What if you could detect smoke in the air before it is visible? Image: ETS Laboratories

I thought if I had some concrete data about the smoke in the air, the system should be able to warn me or at least give me information instead of me going outside and smelling the air myself.

So you’re saying that you’ve connected a range of sensors on your property and they feed information back to a centralised data platform? What does this look like in practice?

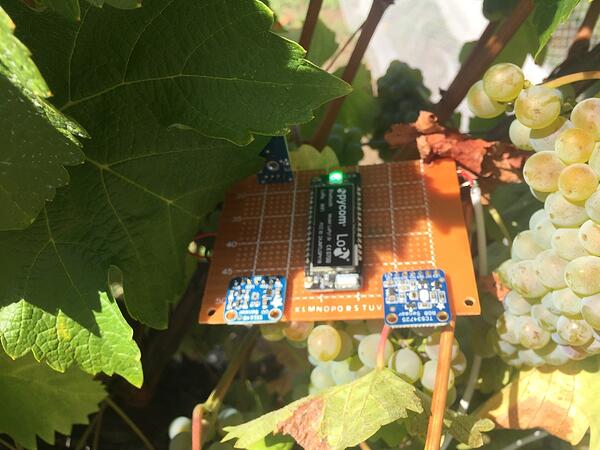

Yes, that’s right. There’s a cluster of sensors in the vineyard. I might have a smoke detector, a temperature sensor, soil moisture sensor, leaf colour and moisture sensors at various locations. They send information back to a server or the cloud over an internet or IoT network. From there it’s displayed on a dashboard or website, alerts are sent. In some cases certain alerts can activate other more complex sensors such as infrared cameras so I can see what’s happening and quickly change my farming activities during an adverse event.

It’s not just about the sensors though. Multiple data sets can be integrated. Our smoke detection solution pulls data from available sources like the Bureau of Meteorology and Tasmania’s fire watch website. Then we overlay our own sensor data readings to get a visual map of where the fire is, which way the wind will blow, and what our smoke readings are in real time.

It gives the farmer the information they need to make the decision.

What technologies are you using?

We’re experimenting with a range of IoT solutions and networking solutions. We’ve installed multiple temporal sensors and a LoroWAN network and then linked all of this with an analytics platform using Amazons AWS.

On the analytics side, we’re using Dynamo DB and are looking into computer vision and machine learning around the processing of imagery and finding patterns and irregularities. We have sensors for air temperature, air quality, soil moisture, leaf moisture and we’re experimenting with visual sensors and other data sets.

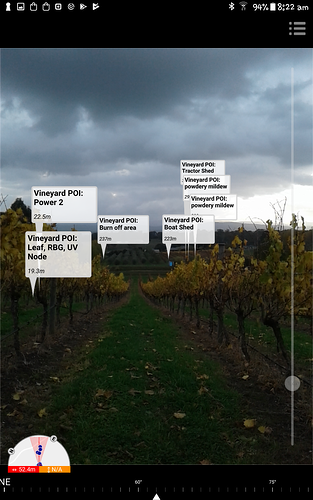

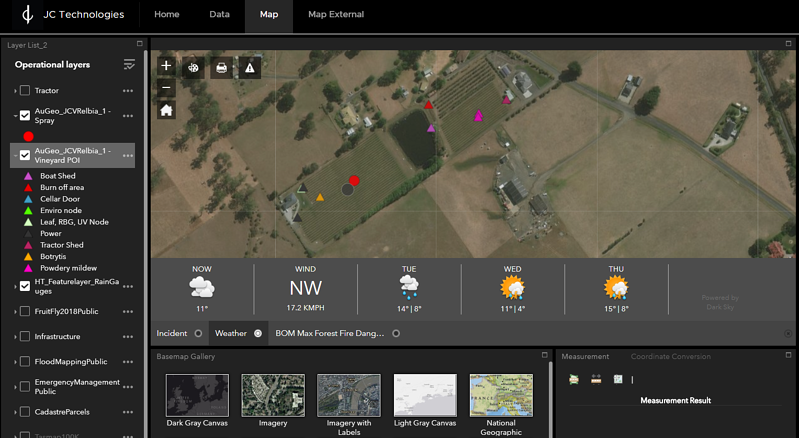

Lastly, we’re building a custom-integrated visualization platform to view all this data. It’s a GIS platform, so a map-based visualisation and dashboard with graphs and alerts based on the data and an AR app.

Aren’t there already solutions like this on the market place?

The agtech space in Australia is still growing. It’s a lot bigger in New Zealand where there are sensor-based systems and remote monitoring for a majority of farms.

Most solutions available in Australia are quite niche and separate, for example a water irrigation system, a microclimate system and an acoustics system and they all have proprietary software. I wanted to bridge the gap and bring it all into one interface.

What insights have you gained so far?

A lot of the information hasn’t been surprising, which shows the system is working. At its most basic level, the analytic interface displays visual readings of temperature, smoke particles in the air, moisture on the leaves, and soil composition. But the next level of analysis is in combining data sets to reveal patterns and correlations you wouldn’t have thought of.

From here, it progresses towards data sets talking to each other and taking action based on real-time information.

Do you have an example?

Our temperature sensor and frost mitigation system. Once our temperature setting hits a threshold of three degrees it will turn on another imagery sensor to see if there’s frost settling on the vines. It’ll alert you so you can see what’s happening in real time. The camera can see if frost is settling on your leaves and see whether your frost mitigation measures like sprinklers are or aren’t working. From here you can make a decision and be agile during a frost event.

The imagery data like this is where the real insights will start to come.

There’s also power in how the data is presented. Once all your information is visualized in a single map interface, you can see things you hadn’t before. For example topography and temperature mapping has shown why that certain pockets of vines on slightly higher land have budded before the others.

How does this translate into cost savings?

At this stage it’s more about protecting against a financial loss, and this system can do that. For example the temperature sensor and frost mitigation solution.

We can also quantify farming methods. For example putting GPS units on sprayers to see what chemical is sprayed on what block and when. Then in future years we’ll do targeted spraying rather than spraying the whole vineyard at regular intervals. That quantifies into a direct cost saving.

What technological challenges do you face in implementation?

The IoT sensor space is difficult at the moment. You can buy sensors from a provider who can also connect the devices and help you solve your specific problem but not a price point that is efficient for farmers.

Our solution is aimed at reducing the cost of these sensors, and the whole system, for farmers at all scales.

How have you tackled this?

I’ve been building parts of a sensor myself. But building the sensors and getting them communicating is a challenge in itself! This is okay for testing but we’ll need another solution for productisation. There are a couple of products due to hit the market soon that will just plug in and transmit the data.

How are you going to productise this solution?

As far as the business is concerned, we provide the analytics and the communications solution, not building of the sensors themselves. We’re aiming to be sensor agnostic, to ensure we offer people the best technology on the market and the best price point.

I’m the analytics specialist and can help farmers use this data to make better decisions.

What advice do you have for businesses or farmers wanting to use data to gain more insights?

A few things:

- Know what to with the data when you get it. I’ve seen companies where staff and management understand the data but then don’t know how manipulate it, or pull out what they want in a different way. I like bridging that gap.

- Also a lot of companies build generic technology and don’t understand the individual problems. Successful projects are done by consultants and companies who really know their industry and specific problem. They have the on-the-ground experience versus just a good technology idea.

- You don’t want a system that’s only supported overseas – you’re going to need that local expertise and physical support.

- Finally, I think the real world problems don’t necessarily need the most expensive technology or cutting edge technology. It’s about first know the problem, then finding the solution, and finally using the best technology to achieve it. It might be innovative to use a spreadsheet to solve a problem – that might be the best tool for that situation and that’s ok.

Read more about the work Fiona does with Nukon: How digital transformation technologies are enhancing business operations

Nukon helps clients achieve more visibility of their operations across utilities, manufacturing and food and beverage to name a few. Find out how real time data can improve day-to-day operations by downloading our free guide: Driving operational efficiencies through real-time data.