People clearly recognise the value and importance of digitalisation and Industry 4.0. Successful digital transformation can quickly remove some of the biggest pain points for a business and shift an organisation's goals to better serve its customers.

The challenge for many businesses and organisations that we talk to, is that they are unsure how to begin a digital transformation, or what it looks like in practice. To help, we’ve put together this quick start guide, exploring our 6 steps to a successful digital transformation.

Let’s get started!

What does digital transformation look like?

We’ve worked with clients to fully digitalise their quality systems, increase visibility in warehousing, analyse water assets using predictive machine learning, and provide real-time operational awareness through IT and OT integration.

While each of these projects is inherently different, the general approach for implementing digital change is the same, guided by the following six steps:

1. Current state and pain point analysis,

2. Create a vision for the future state,

3. Gap analysis and roadmap development,

<Decision point>

4. Solve ONE problem (pilot project),

5. Validate solution and update roadmap,

6. Measure ROI and delivered value.

<Move on to next problem>

We’ve divided these stages of the digital transformation process into two blogs:

PART I: Getting started (steps 1-3) – you are here.

PART II: Implementation (steps 4-6).

We’ll jump into Part 1 now – but an important point before you read on:

Implementing change to drive performance must focus equally on people, process, technology, and data. These are the pillars of success – if you simply focus on technology without addressing the remaining three critical pillars, change management will fall flat.

Part 1: Getting started with digital transformation

1. Current state and pain point analysis

“Begin with the end in mind” – Steven Covey 7 Habits of Highly Effective People

Steven might be jumping the gun here. Aside from the vision, which will guide what follows, the first step in getting started with digital transformation should be to understand where you are now.

What: Conduct a current state assessment, which involves looking at your current processes and information flows, and benchmarking these against similar businesses.

Timeframe: 2-4 weeks.

How: A current state assessment can be conducted internally or by a digital transformation consultancy company such as Nukon.

Action: Take the time to collect qualitative data, such as KPIs and reports, and quantitative data, such as the description of recurrent troublesome situations. This will help define the best approach for the next phases of the project. Ask questions and observe processes. Involve operations, production, supply chain and IT departments to gain a thorough understanding of your strong points, challenges, and opportunities.

Why: Solve the right problems by uncovering the strengths and weaknesses of the current systems and processes. Pareto analysis helps in identifying initiatives with a high return value. Think about digital transformation as a marathon, not a 100-metre sprint. Saying this, building in some early wins will revitalise efforts and build strong internal support for the program. This stage provides a baseline for the technology roadmap.

Scenario: e.g., A frozen food manufacturer believed they had an MES problem. A current state assessment identified problems and opportunities for improvement that would have a far greater return than an isolated MES upgrade, including projects that could reduce raw material costs by 2% and improve throughput by 10%, adding up to tens of millions of dollars in annual savings. Importantly these solutions were around people, process change and technology.

How Nukon can help: Nukon will consult with your business and perform data collection including interviews, observation, data analysis, and benchmarking to provide a true current state assessment and recommendations on opportunities to improve. We provide industry benchmarks by ranking your processes on their maturity, level of digitalisation, and efficiency. A methodology with templates and tools is used to keep this as efficient as possible. A business case or ROI study can be developed.

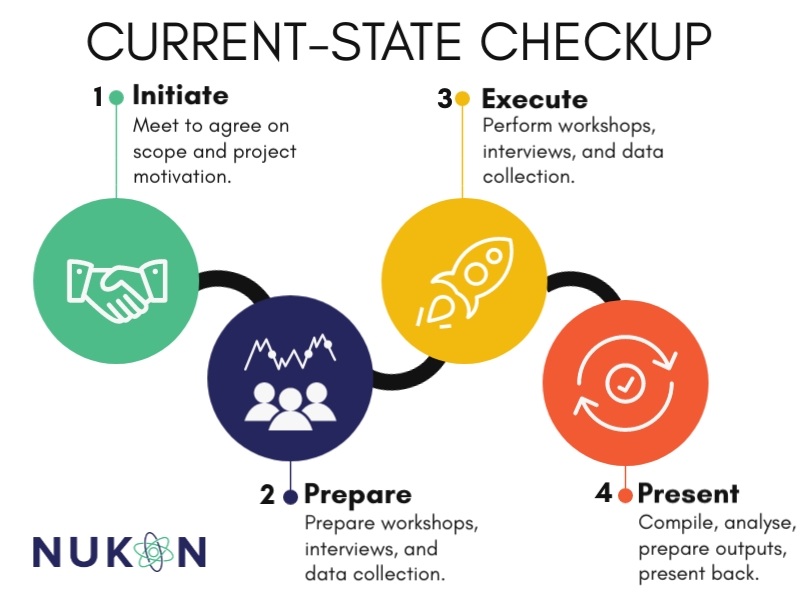

Get started today with our simple current state check:

- Initiate: Meet with the engagement sponsor to agree on scope, terms of reference and motivation for the project,

- Prepare: Prepare materials to facilitate workshops, interviews, and data collection (qualitative and quantitative),

- Execute: Perform workshops, interviews, and data collection,

- Present: Compile the information collected, prepare outputs and present back to the key audience.

2. Create a vision for the future state

It may seem like an obvious question, but it pays to stop and ask: What's the problem we are trying to solve?

Is it improved quality, faster response times, reduced costs, better visibility, or something else?

Next, we need to determine which conflicting goals will provide the most business value. Here we recommend conducting a value driver assessment to help identify where your money should be spent.

What: A value driver assessment is the study of key business drivers to identify the best digital transformation value areas.

Timeframe: Generally, of short duration – varies based on complexity and size.

How: First, get started with a strategy meeting. Meet with key business leaders and consider:

- The vision,

- Outputs from the current state assessment,

- Key drivers for business success and industry competitiveness.

Action: Conduct the value driver assessment, using the following four steps as a guide:

- Review the current state assessment, which will have uncovered your challenges and opportunities,

- Align your key business drivers with the Industry 4.0 value drivers (pictured below), considering current and long-term strategy,

- Identify the potential digital transformation opportunities for each key driver(note the table below provides a basic representation of options and you may benefit from a vendor-agnostic technology provider’s input here),

- The complexity, costs and change impacts should also be rated to provide an overall view of the value potential.

A basic representation of Industry 4.0 levers mapped against value drivers for manufacturing. Credit: McKinsey

A basic representation of Industry 4.0 levers mapped against value drivers for manufacturing. Credit: McKinsey

Why: Sometimes to know where you want to go, you need some options on the table. While this step could be done on your own, the value comes from having a technology and industry specialist present you with options.

Scenario: e.g., Our frozen food producer’s focus on on-time delivery might translate into key Industry 4.0 value drivers of time to market, supply/demand watch, quality or inventories. Next, the Industry 4.0 levers will need to be considered in the context of the business’ specific pain points, current processes and opportunities outlined in the current state assessment.

How Nukon can help: We can help you identify business requirements and determine the biggest lever you can pull with Industry 4.0. Following the current state assessment, we’ll look at business processes and the strategic vision, and consult areas of your business (including ordering, product fulfilment, quality production scheduling, operations management, and customer support) to achieve a clear, financially viable direction.

3. Develop your digital strategy

A digital strategy should show how progress will be made toward implementing the desired change identified in step 2. This will be aligned to the digital maturity of the organisation and may trigger an evaluation of competing technologies to implement parts of the roadmap.

What: Conduct a gap analysis and begin your technology roadmap development. This involves identifying a series of time-bound milestones that gradually build digital capability across processes, people, infrastructure, applications, and data management.

Timeframe: 2-4 weeks. Typical horizon 1-5 years.

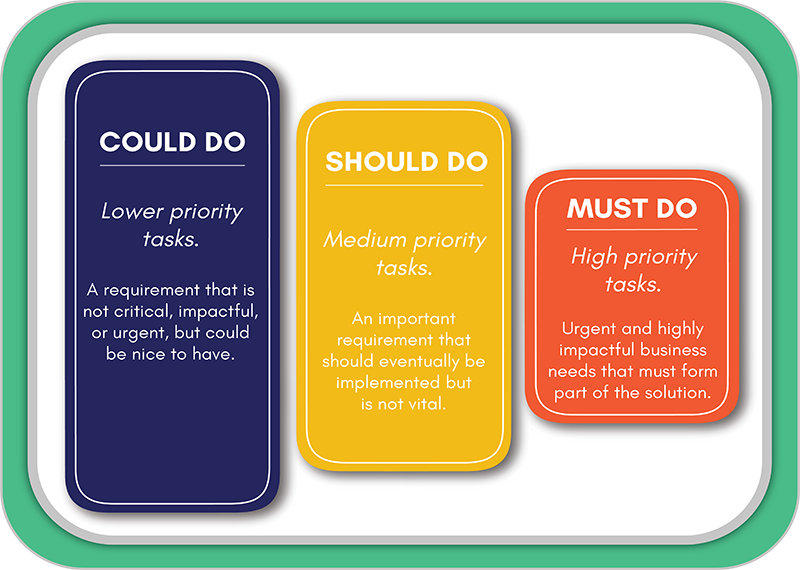

Action: Time to discuss your planned outcomes. Collaboration is key for your digital strategy and a critical phase before moving into implementation. Gather key business leaders to brainstorm and finalise your desired business outcomes. At Nukon, we like to use the simple yet valuable: ‘could do, should do, must do’ framework to identify digital transformation goals based on hierarchical needs.

Nukon’s ‘could do, should do, must do’ framework.

Nukon’s ‘could do, should do, must do’ framework.

Once you have a high-level roadmap, identify the specific projects required to reach each milestone and business capability. This will be different for each organisation, depending on the outcomes from previous activities, and desired goals for digital maturity.

Why: The digital strategy or roadmap will keep you headed in the right direction, and avoid budget pitfalls and misdirected resources in your digital transformation journey. Outlining a roadmap and a vision also helps with change management and bringing everyone along on the journey. With a clear strategy, you'll avoid taking a piece-meal approach with different people pushing and pulling in different directions – all wanting the same thing.

Scenario: e.g., Our frozen food manufacturer wants to focus on the value drivers of quality and time to market. They have a few key processes that are still paper-based, such as quality and planning. They see that having a strongly connected worker and real-time visibility of events will support on-time delivery and streamline quality and planning processes. An example high-level approach to achieving this would be to develop multiple streams in parallel while driving maturity up to increase end-to-end automation:

How Nukon can help: We can develop a realistic roadmap to get you from where you are now, to a position to realise your future value drivers. We will ensure the roadmap is moving you up the digitalisation maturity curve for people, processes, and technology.

Some digital strategy tips:

- Be realistic about your time frames,

- Don’t try and take on too much at once,

- Keep the roadmap at a strategic level but consider technological requirements,

- View the roadmap as a journey, not a one-time project,

- You don’t need to make ‘one big bang’; make modular, incremental, and measurable improvements,

- Be patient – often the initial steps will be piloting and small-scale testing to validate assumptions and benefits, followed by getting the foundational infrastructure in place.

Wrapping up Part 1 of your digital transformation journey:

We’ve covered the first three stages of any digital transformation project:

1. Current state and pain point analysis,

2. Create a vision for the future state,

3. Gap analysis and roadmap development,

After these steps, you’ll have a firm understanding of where you are now and where you should be focusing your digital transformation efforts. You’ll have identified the most valuable Industry 4.0 drivers and will have a clear roadmap as to how to achieve them.

From here, you will need a fine-tuned and integrated process supported by the right technologies to implement an effective program. This will be the difference between delivering the strategy and achieving a competitive advantage or having the program fall flat.

Time to make some key decisions and move to implementation.

Read Part 2 in our series: 6 steps to a successful digital transformation (Part 2: Implementation). There, we'll explore stages 4-6 of digital transformation, following your all-important decision point where you implement change:

<Decision point>

4. Solve ONE problem (pilot project),

5. Validate solution and update roadmap,

6. Measure ROI and delivered value.

<Move on to next problem>

If you're interested in learning more about we can help implement change to drive your business, check out our Nukon way of working blog.

Or if you like, read our free guide to integrating IT and OT systems. This is often a foundation step in any digitalisation progress, and will set you up to be able to scale other business-wide improvements.